Read about the Toughware Equilux here. All prosthetic hooks, prehensors or grippers lack the option of using industrial grip pads. Pads that are readily available, cheap, durable and that the user can easily switch.

And grip pads and grip gloves are a real issue. As posted before, grip pads must be soft, possible to clean, easy and cheap to replace and convenient. These requirements are in part mutually exclusive. With the knife holding issue of the Equilux, what easier than to mount some standard bike rim brake pads and take it from there.

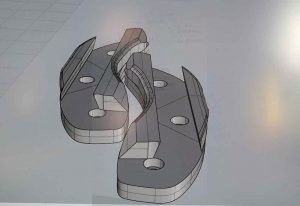

Technical solution – adapter for industrial grip pads, here: rim brake pads

PLA fit test

First I approximated the interface / adapter pieces for the Toughware Equilux in 3D. I made some holes for the screws, and provided mini-rails to slide the rubber pads in.

I printed them in gray PLA (what was just there really) just to see whether the adapters would fit. So I mounted them on the hook. Notice my almost perfect tolerances here – screw heads are minimally protruding to secure (but not jam) the rubbers.

Then I used Shimano race bike style rim brake rubber pads that I had lying around. Rubber slides in, done.

The rubber is placed right where the grip is. Industrial grip pads always will exhibit some form of shape mismatch, so the task of the interface adapter is to provide useful placement.

Other claw with a different brake rubber, one that is a little bit softer.

I tested this with normal gray PLA printed with 60% infill, but I then considered to get these in a more enforced material. What if it breaks, I thought. Not that they felt fragile.

PLA with 30% carbon fiber

Basically this is the cheap Aliexpress variation of the original carbon fiber enforced “Protopasta(R)” PLA – which prints perfectly on a Makerbot Replicator + 5th generation. Absolutely no troubles there.

Carbon fiber PLA prints of the adapter.

Mounted one claw.

Pushed rubber pad inside, with a tiny whack with a hammer to get it to slide over the screw heads.

The other adapter. Easier to mount when pushing screws trough first.

Mounted. Pencil placed into hook for easier typing.

Motivation

Any industrial grip pad substitute probably is cool for testing.

Not that it is necessarily required to use, of all things that are available on this planet, bicycle rim brake pads. I just had some extra pads lying around. As these don’t get better by lying around some more, I decided to put them to use.

The proof of concept was really what I was after.

We need the world to know that it is absolutely possible to equip a prosthetic hook or prehensor, a gripper or device, with any type of soft grip pad cover that the user can easily replace, and that is very easy to buy anywhere.

That is a type of thinking we urgently need in prosthetic arm and device design.When I wear an i-Limb, and a 700 glove perforates within 10 minutes, and it must be replaced by a prosthetic technician, I will spend 3 hours plus a lot of money on a 10 minute use of that device. It cannot possibly be that any engineer, marketing or sales person, or whatnot, “has a hard time understanding why we do not wear prosthetic arms just that much”? I have not really read that as something engineers, marketing or sales people seriously ask? It is not seriously expected of me, by, say, Touch Bionics user support, to just accept that as reality? But then, life is a miracle and we sure do not know everything.

So, to show that even an arm amputee himself, given a few short moments with 3D software, can make himself a 3D-printed adapter for industrial grip pads, certainly will have its moment in history, as, like, yay. And as you can imagine, there might be other ideas that go in a similar direction.

And this approach is gaining traction. Since the time where I had posted some orange work gloves as option to be worn on the iLimb, I have seen research papers with people putting such orange working gloves onto their research robot hands, without even going into detail about what glove that was, or, without indicating where they had the idea from. I know, you read a lot of really sensible stuff here first, so much, you probably thought it was all your own idea. Life is a miracle though, isn’t it. That is maybe a good moment to indicate that I also use regular bike control cables and cable sheaths on my patented Bowden housing mount revision ; ) I came up with that in around 2010, so I am now doing that since quite a while.

Grip mechanics

The grip mechanics interestingly is a bit different from what one is used to. The non-slanted geometry of the blunt parallel bars makes itself felt when putting these to everyday use.I guess I will observe, take note, and report back later once I have a more comprehensive conclusion.

- Cutting with a knife. It is currently not at all possible to cut with a table knife with these pads. The Toughware Equilux however is, with the industrial pads, in excellent position to stabilize a fork with full control and pressure. For knife cutting I will need to add grooves to the pads with a sharp knife.

- Grip slip and grip grab seem to exhibit a more rectangular behavior. This can be helpful actually, but I have not really considered the in-flighte trouble shooting / failure aspects of mechanical grip failure and grip success versus objects, yet.

- These pads are really nice to objects. They do not scratch stuff a bit.

- Their lack of porosity, lack of textile and lack of microstructure makes them easy to keep clean. That is truly nice.

- Softness / Shore durometer hardness is the determining factor here. Within brake pads, BMX seems to be the type of bike where softer pads are used for violent stopping power at expense of shorter longevity.

Try yourself

If you want to print the adapter pieces for bike pads out to test for yourself, here are the 3D files:

With the brake pads, just get the ones that fit ; ) They have a trapezoid cross section mount and usually fit Shimano road bike rim brakes, or variations thereof. Or just go and make your own adapter pieces, it’s definitely not hard.

So, maybe cut knife grooves into these pads. And to see where one can buy the softest rubberysiest pads. The trade-off always is better grip quality against better longevity – and with this setup, for the first time in a long while, I only want better grip quality.

Ordering brake pads: